- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Evaluating air quality

- By Mike Meyer

- September 2, 2016

- Article

- Welding

Sometimes it’s easy to know when you have an air quality problem: The air is visibly dirty, the facility smells bad, and breathing is unpleasant. But subjective observation isn’t always enough. Understanding your risks and selecting the right remedy require careful evaluation of your fume characteristics, facility layout, and airflow patterns.

Taking Air Quality Readings

Measuring dust concentrations at different points in your facility will help to quantify your exposure risks. Dust concentration meters measure the total levels of particulates in their immediate vicinity.

If your processes generate a consistent amount of particulate at all times, it may be enough to take a few “snapshot” readings and average the result. However, many facilities will want more sophisticated analysis of how air quality changes over time as their industrial processes cycle. More advanced dust concentration meters take measurements at increments over an entire 8-hour shift. This allows plant managers to see both peak measurements and total particulate exposure over the time period.

This is important because most air quality regulations are given in terms of an 8-hour time-weighted average (TWA); in other words, you need to know not just the amount of particulate generated at a given time, but the total exposure that workers will have over the course of a standard shift.

Because dust and fumes travel throughout a plant via air currents, it’s important to take air quality readings in different parts of the building. Meters should be set up at breathing-zone height (roughly 5 feet off the ground) at key points around the facility, including next to the fume-generating processes and in other areas where people congregate, such as workstations and aisles. Taking measurements in a grid pattern throughout the building will help you see how fumes are propagating and where they tend to collect.

Characterizing Particulates

Understanding total particulate exposure is a good first step, but it’s also important to know the makeup and character of the dust or fumes. Exposure risks depend on the size and chemical composition of the particles generated.

Different processes, base materials, and consumables can produce vastly different kinds of dust and fumes. For example, particulates from thermal processes such as welding tend to be very small (between 0.3 and 1.0 micron), while mechanical processes such as cutting and grinding can produce dust particles large enough to be easily seen by the naked eye. Size matters: while larger particles may cause more immediate irritation, smaller particles can more easily settle into the lungs or even make their way into the bloodstream.

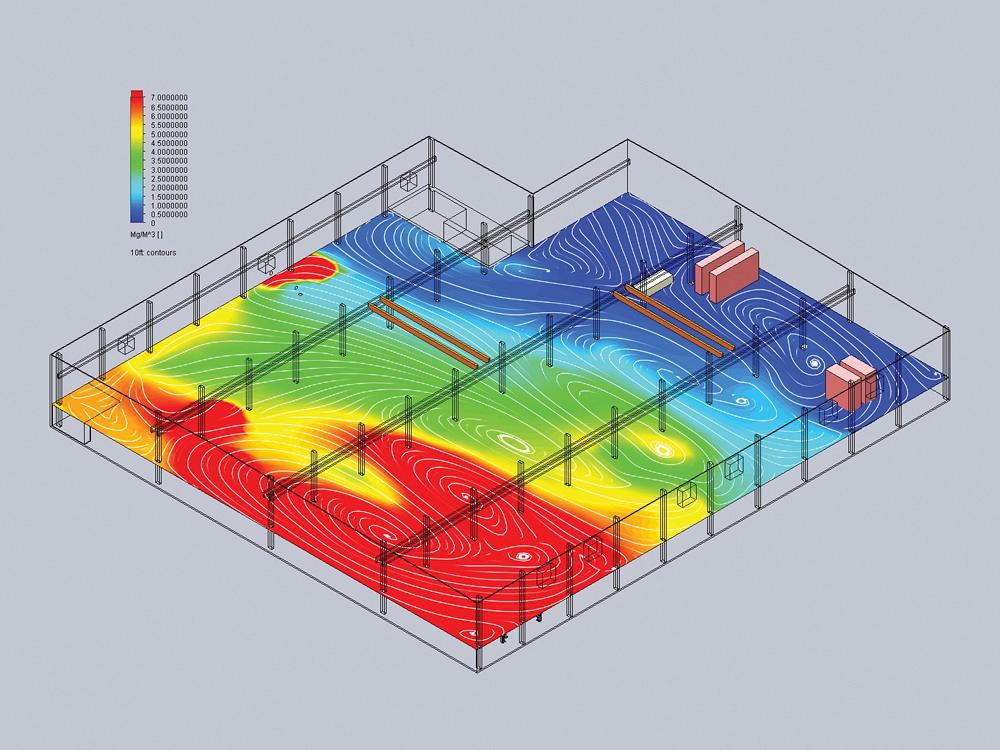

Analyzing your current trouble spots and airflow patterns will help engineers design a more effective air quality system.

Composition matters too. Exposure to dusts containing components such as hexavalent chromium, manganese, or beryllium is much more dangerous than exposure to similar volumes of dust made up of less noxious chemicals. There are specific exposure regulations for each of these elements or compounds; it is thus entirely possible to be within regulations for total particulate exposure but in violation for exposure to a particular element.

To be sure that you are complying with all regulations, you need to know not just total dust concentration, but also the exposure levels for particular elements or chemicals of concern. Air quality engineers can approximate these levels by looking at the processes and materials being used. For example, when you are burning welding wire, 5 to 8 per cent of the wire consumed will convert to welding fumes. Total exposure levels to different elements can be extrapolated from these total particulate measurements if the composition of base metals, coatings and lubricants, and consumables are well understood.

In some cases, companies may want to conduct an analysis of their fumes in order to get precise measurements. This is especially important if the total particulate level is close to the upper allowable limit, or if estimates for a particular element indicate that you may be close to or over the limit for that element. In this case, dust samples can be collected on special filters inside the dust concentration meter. Samples are sent to a lab for chemical analysis, a process that generally takes about two to three weeks.

Understanding Airflow

A third crucial component that air quality engineers will evaluate is how air moves through the building. Every facility has it’s own unique airflow patterns, which influence how weld fumes propagate through the facility, where they end up, and where they linger. The dust concentration meter readings at different locations will provide important data. But designing an effective remedy also requires a more in-depth evaluation of the existing airflow patterns.

To be efficient and effective, your air quality remedy should be designed to work with your airflow patterns, not against them. The type and location of existing ventilation and HVAC equipment, location of windows and doors, equipment position, temperature variations, and other factors influence airflow currents throughout the building. These currents can have a great deal of impact on the efficacy of dust capture and filtration equipment. If you try to work against the currents, your air filtration equipment will require a much higher capture velocity, resulting in significantly higher energy use.

Capture velocity needs are also affected by the processes themselves. Processes that aggressively “push” particulates into the air will require much higher capture velocities than those that allow them to simply waft into the air, such as fumes rising from freshly welded parts in a cooling bin.

Evaluate Now to Save Later

Spending some time up front for evaluation of your existing state will pay tremendous dividends when it comes to system design. No matter how bad current air quality is, it is possible to design a system that will meet and exceed air quality regulations for both total particulate and individual elements. Understanding the nature of your fumes and the airflow characteristics of your facility will help engineers design the most effective remedy for the least amount of money.

Fixing air quality issues should never be a matter of simply throwing “more and better” equipment at the problem until it goes away. A thoughtful approach to site evaluation will help you meet your goals without spending more than you need to.

Mike Meyer is a senior engineer and executive technical director at RoboVent, 888-762-6836, www.robovent.ca.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

BlueForge Alliance partners with Nuts, Bolts & Thingamajigs to develop Submarine Manufacturing Camps

Orbital tube welding webinar to be held April 23

Portable system becomes hot tech in heat treatment

Cidan Machinery Metal Expo 2024 to be held in Georgia May 1-2

CWB Group launches full-cycle assessment and training program

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI