- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business of Welding: Time is money - are you allocating yours properly?

- By Orest Protch

- August 24, 2016

When it comes to starting a business and choosing a great spot for it, everyone is familiar with this mantra: “Location, location, location.” We will call this the 3 L’s. Unless you have something that is in demand and not available anywhere else in the vicinity, you have to be very selective about where you open your doors.

To stay in business, a welding company also has to have its own version of the 3 L’s, and that is “burn rod and wire, burn rod and wire, burn rod and wire.” Anything that takes a welder away from this focus is wasted time and money.

Whether you have three welders or 100 working for you, they are making money for the company only when their machines are producing that gratifying electrical buzzing sound that means dollar signs, the sound of money going into the bank to pay the bills. That is the sound of weld metal being deposited.

Have you ever wondered why some welding companies are always making money while others that offer the same services cannot seem to stay on the good side of their bank loan manager?

Notice that I did not say "some welding companies are always busy and always making money.” Just because a welding company or a welder is busy does not mean that they are making money. One verb has nothing to do with the other when it comes to putting money into the bank.

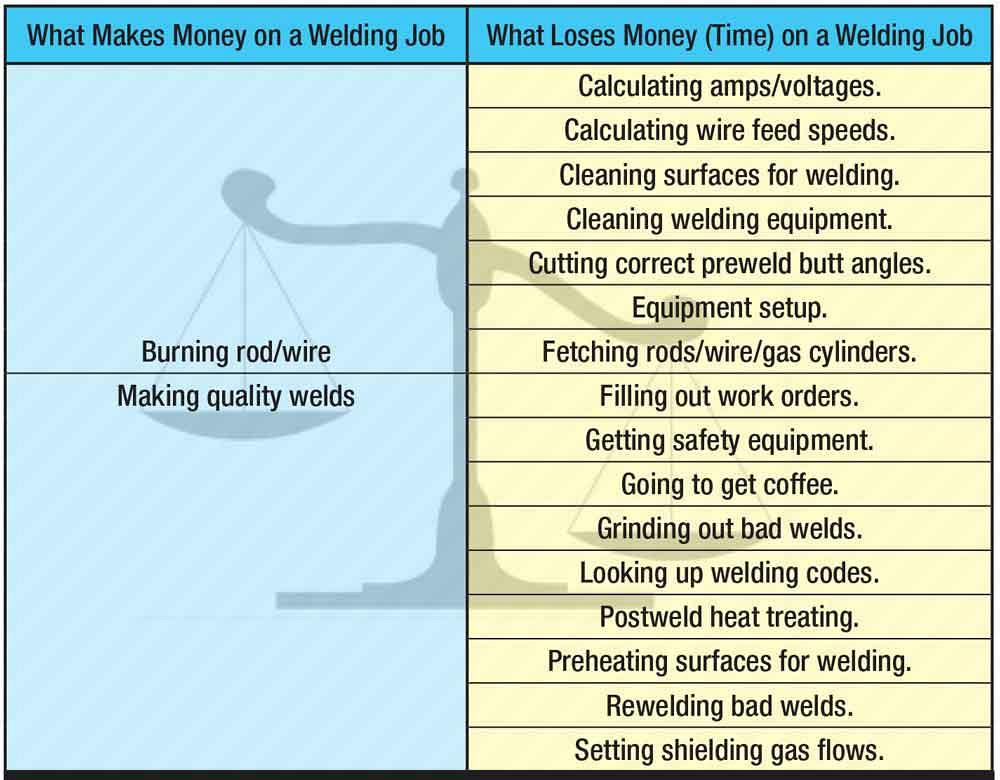

There is a scale to consider in a weld shop and it has to be balanced. If not, you are losing money. Take a good look at Figure 1 and consider where your shop uses most of its resources.

Figure 1: The balancing act of when and how a welder is making money is quite simple to figure out. When rod or wire is being burned to make quality welds you are making money. When welders are not burning rod or wire, how are they making money? Remember, not all jobs or contracts pay by the hour.

Let's look at Figure 1 in a different way. If we are on a job site that does not pay by the hour but by piecework, meaning we get paid by how many lengths of oil pipe we weld, or by how many widgets we fabricate, or by how many inches of good corrosion-resistant overlay weld we lay down on a bridge, there is only a small percentage out of every hour of total work that we are making money.

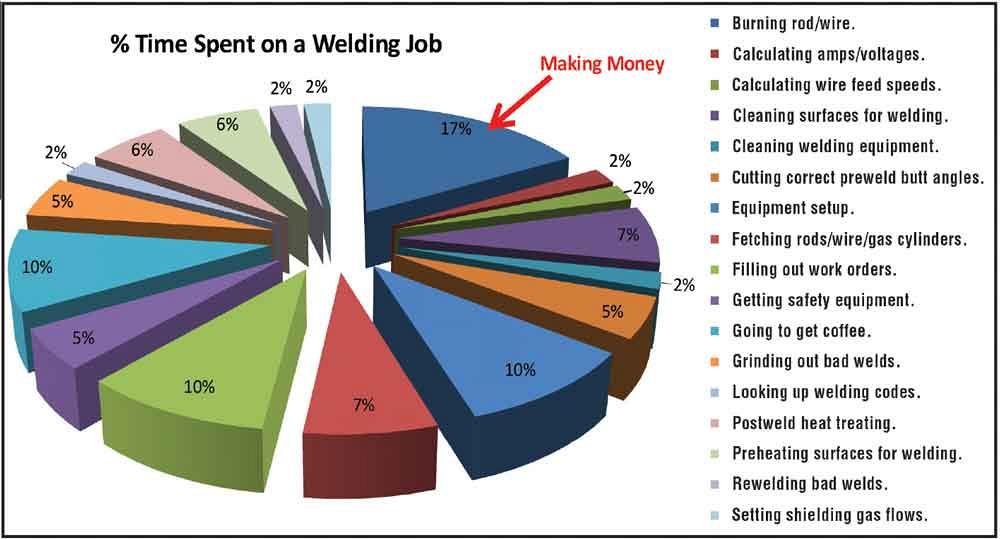

Figure 2: This chart shows how small a piece of a time pie actually is putting money into the bank on a job that does not pay by the hour. In this case, only 17 per cent of the time is weld metal being deposited.

How much time are you and your welders actually spending depositing weld metal? No matter what the state of the economy or how deep a recession is, some welding companies keep making money. Others struggle or go under even during the best economic times.

So how can we make sure our welders are using their honed skills to maximum advantage? We free up their time to do so.

If a pressure welder is being paid, for example, $40 per hour to work on a pipeline and there are five of them on a team, that is a lot of talent and money that need to be used wisely. You can free them up from some of the noncritical jobs that make up a welding project by getting them a qualified helper to not only do a lot of the more menial jobs but also to do most of the other important jobs, that go along with the work. See Figure 2 for a sample of these.

You may have welders’ helpers who make $10 per hour to do cleanup, grind bad welds, and even fetch coffee, but every welding job site has tasks that require more knowledge than a basic high school diploma but less than an engineer. This is where a welding technician or a metallurgical technician can play a role.

A metallurgical technician has the training to do a lot of code prework, is knowledgeable about welding rod/wire selection and storage, is or can be trained in how to do bevel cuts to get pipes ready for pressure butt welding, and perform pre- and postheat-treatment and a host of other routine tasks that take a highly skilled welder away from his primary job.

Look again at the unbalanced scale chart in Figure 1. The right-hand side has a lot of tasks that a technician could do and a lot more than a less trained, low-pay-grade welder helper could do.

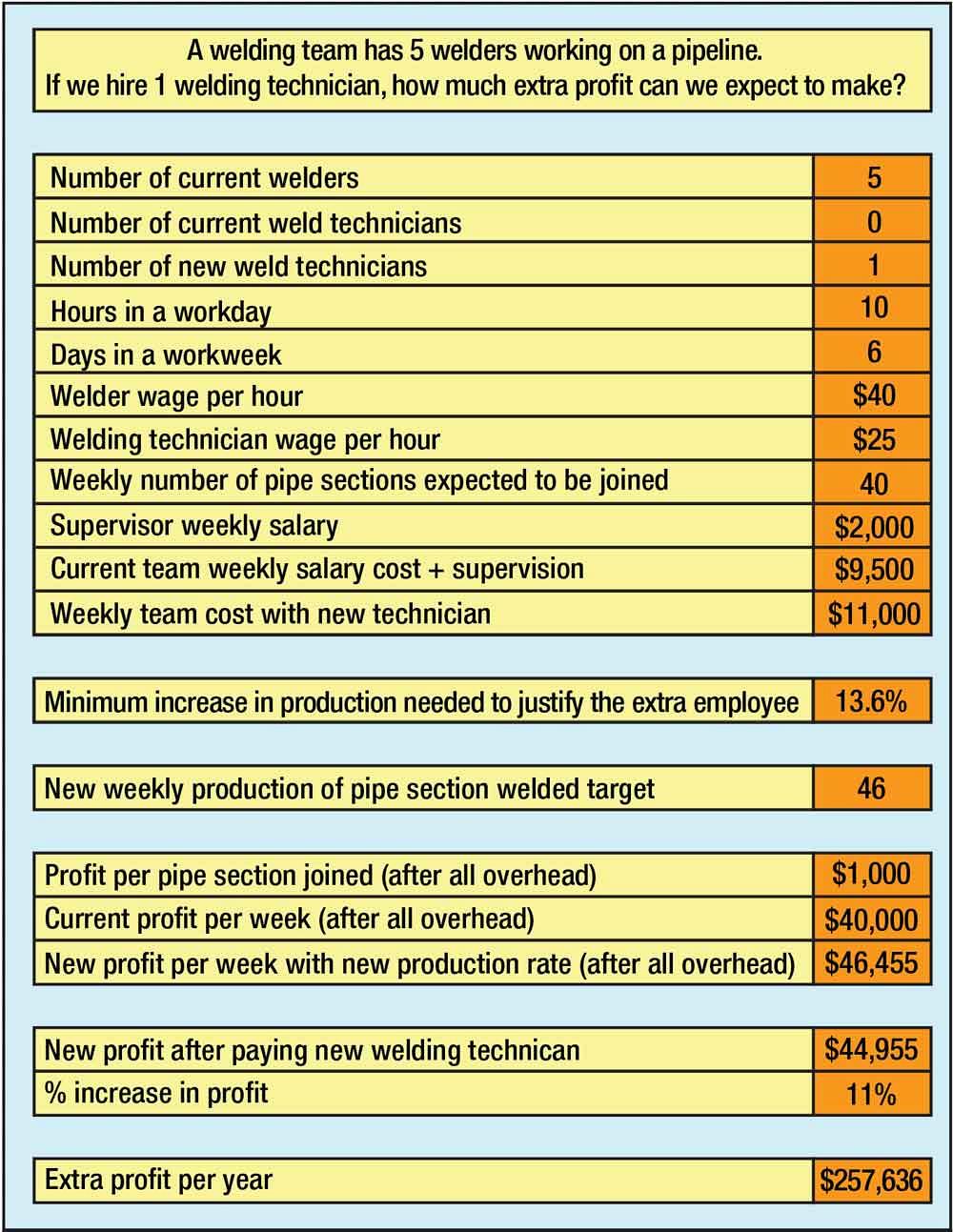

Let's work through a simple spreadsheet (Figure 3) that shows some simple calculations to see what an extra trained employee could do to the profit picture.

Figure 3: Hiring a welding technician or metallurgy technician to perform support tasks for a skilled welder can put money in the bank. Generally, each employee should create a factor of three to four times their salary in extra profits to justify their position. In this example, the ratio is around 3.5.

In this example, our team of five welders and one supervisor is being augmented by a trained welding or metallurgy technician. This individual has more training than an unskilled welder helper and is able to not only do the grunt work that every job needs done, but also the more skilled tasks that are on the right side of the chart in Figure 1.

Using the numbers in Figure 3, we see that the technician position needs to create the opportunity to increase production by a minimum of 13.6 per cent to pay for the position and to turn an extra profit resulting from the expected increased production. Any employee in any business needs to create three to four times their salary in profits to justify their position. In our example, the yearly technician salary of $78,000 should create an extra profit of more than $250,000 by allowing more welded pipe to be laid down in the field because skilled welder time is freed up for actual productive work.

This simple math concept is underused by many companies when it comes to understanding how to justify new skilled-trades positions.

Understanding simple financial math concepts is key to helping you to maximize your profits in a tough economy or in a great economy. Let your competitors be the ones that feel the power of your improved performance as you leave them in the dust.

Orest Protch facilitates seminars in basic welding and machining metallurgy for apprentice and journeymen welders, machinists, fabricators and engineers across Canada. He can be reached at oprotch@hotmail.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Trending Articles

CWB Group launches full-cycle assessment and training program

Achieving success with mechanized plasma cutting

3D laser tube cutting system available in 3, 4, or 5 kW

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Welding system features four advanced MIG/MAG WeldModes

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI