- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business of Welding: Allocating Welding Overhead 101

- By Orest Protch

- April 11, 2016

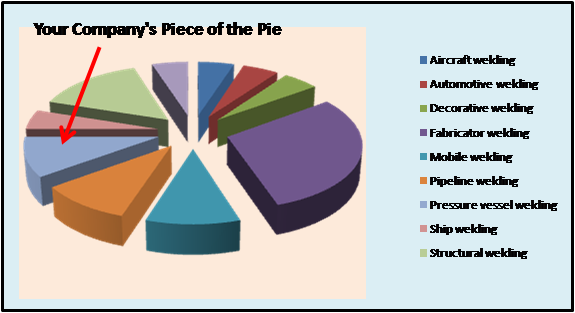

All welding companies, regardless of size, are chasing a piece of the economic pie that their welding services cover (see Figure 1). Very few can be all things to all customers, so each tends to specialize in a few services.

One problem many welding companies struggle with is how to calculate the price of their services such that they can be cost-competitive but still turn a profit.

Figure 1: Your welding business competes for a part of the welding contracts in your area of expertise.

Mobile welding truck operators have it relatively easy figuring out their hourly rate as they usually calculate it one of two ways. One way is that the customer, such as a pipeline builder or a pulp mill undergoing an annual shutdown for repairs, will pay a set price for a welding truck. For example, this could be $100/hour plus the cost of consumables. The welding truck owner/operator has to determine if this will pay the overhead.

The second way that a welding truck owner/operator charges out their work is that they simply add up all the monthly carrying cost of the equipment, including insurance and interest payments, and then add in a working wage and the cost of the consumables. They then charge whatever the market can handle.

In the late 1990s when I worked at a pulp mill, welding truck operator/owners were earning $140/hour, which was very good money in those days. Several dozen of them did the shutdown circuit and kept busy all year as the mills staggered their downtimes to make sure there were enough tradespeople of all types to go around.

But then so many others decided to get in on the action that there was a glut of welding trucks and the market got saturated. The half-dozen pulp mills in the general vicinity got together and lowered the price they were willing to pay for a welding truck – down to $65/hour. Some owner/operators parked their welding trucks as their costs exceeded this amount, while those that remained had to suck it up and financially deal with it.

Welding shops, on the other hand, have a much harder time figuring out what their hourly rates should be to bid on a job or contract. An owner/operator of a welding truck deals with a lot less overhead than welders working out of a building. Everything about a building operation, and I mean everything, has to be added up to come up with a total monthly overhead cost of the business. These costs include:

Building maintenance Furniture Groundskeeping Heating Insurance

Internet Janitorial Lunch room supplies Office supplies Power Rent

Safety equipment Security Storage racks Telephone service Toilet paper

Ventilation Water & sewer

A complete overhead list would, of course, be much bigger than this, and too many companies group the various items together into generic miscellaneous categories to simplify their accounting. But doing this opens the doors to waste and even pilfering. I've worked at companies where employees took toilet paper and paper towels home as they knew no one was keeping track. It's the little things that add up that can make a company go under if money is tight.

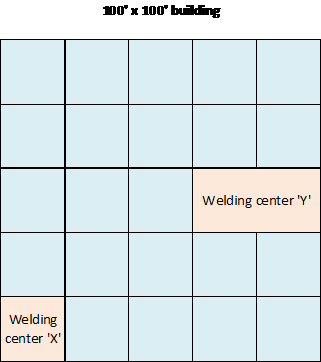

Another way companies lose money is by incorrectly determining the price to charge for their services. For example, say you have a 10,000-square-foot building that has various types of welding equipment set up as workstations. Each of these stations take up a certain footprint, and each footprint comprises the workstation welding equipment, workbenches, special tools and jig racks, shielding gas cylinders, raw material racks, and heating ovens used to store welding rods (Figure 2).

Figure 2: Our welding company building has two workcentres. The X and Y centres are 1,000 and 2,000 sq. ft., respectively.

The Machine Rate Method

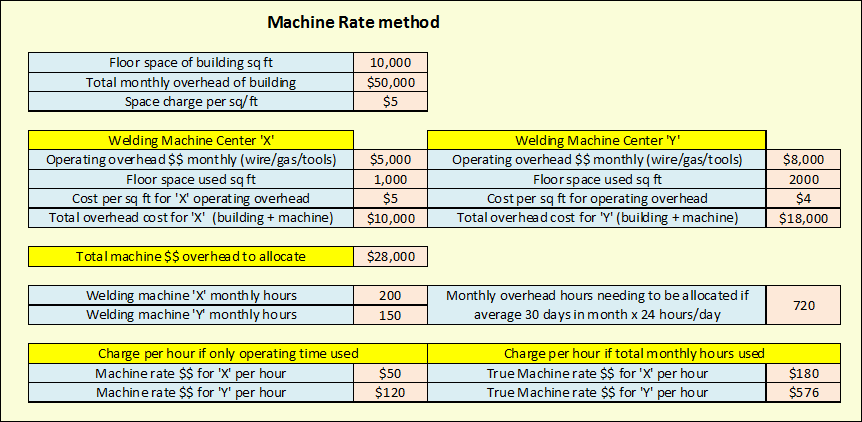

We will do our calculations for overhead allocation by what is known as the machine rate method. We will assume that all the work has been done to figure out what the monthly overhead of our building is; in this case, it works out to be $50,000/month. Since our building is 10,000 sq. ft., the overhead works out to $50,000 ÷ 10,000, which is $5/sq. ft.

The simplified spreadsheet we will be looking at is Figure 3. We will go through the various lines.

We also can then determine that since there are approximately 720 hours in a month, the hourly building overhead allocation by the hour is $50,000 ÷ 720, which is $69.50/hour.

We have calculated what each welding machine centre represents in the square-foot-overhead calculation.

Centre X is $5,000/month, so its overhead is $5,000 ÷ 1,000 sq. ft., which is $5/sq. ft. Centre Y is $8,000/month, so its overhead is $8,000 ÷ 2,000 sq. ft., which is $4/sq. ft.

We add each of these to the building overhead per square foot ($5) and multiply by the footprint of each welding centre. We take this new total for each station and multiply by the footprint for each and get $10,000 for centre X and $18,000 for centre Y.

Figure 3. You can use this simplified spreadsheet to determine the actual overhead cost of each welding machine centre. This in turn will tell you what to charge per hour for each station, not including labour and raw material costs.

In our sheet we can see that centre X works 200 hours a month, so $10,000 ÷ 200 means that the overhead charge should be $50/hour. For centre Y we have $18,000 ÷ 150 hours a month, so the overhead charge is $120/hour.

This gives us a pretty good idea of what we should charge for any work coming out of these two welding workstations.

Now we can add our labour charges and profit margin that we want by the hour. The cost of raw material is also added in now.

We can take it one step farther. Unless we run our welding business 24/7 out of the building, the actual operating hours of each station will be less than the actual 720 hours available in a month. So now we can do a simple ratio of hours to multiply against our calculated overhead for each centre.

For centre X we get $180 vs. $50/hour and for centre Y we get $576 vs. $120/hour.

This is a much more accurate approximation of what we should be charging for work coming out of each station to maximize profits. And 99 per cent of your competition will not be doing this.

Summary

Too many welding businesses charge the same amount per hour for their work no matter where or how it was made in their building. Since a wide variety of welding equipment and support systems are available, operating costs will vary.

This example shows you have various accounting options to choose from to determine the true cost of your welded product.

In our centre Y example, the true calculated overhead cost jumped from $120/hour to $576/hour. If you charge this higher amount, you will be breaking even on the real cost of operating this welding centre.

But do you need to charge this amount? It depends on what the product is and how much competition you face for the service. Maybe you will decide to run one welding centre at a loss to keep one customer and charge more for a second customer. You could also blend your costs together for a number of welding stations.

At least now you have a better idea of how to recover your basic overhead costs as they pertain to each square foot of your operation. This can give you an edge over your competition.

Orest Protch teaches seminars in basic welding and machining metallurgy in British Columbia. He can be reached at oprotch@hotmail.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Trending Articles

BlueForge Alliance partners with Nuts, Bolts & Thingamajigs to develop Submarine Manufacturing Camps

Portable system becomes hot tech in heat treatment

Orbital tube welding webinar to be held April 23

Cidan Machinery Metal Expo 2024 to be held in Georgia May 1-2

Corrosion-inhibiting coating can be peeled off after use

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI