- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

BLM Group plans move to larger facility

- June 10, 2016

- News Release

- Fabricating

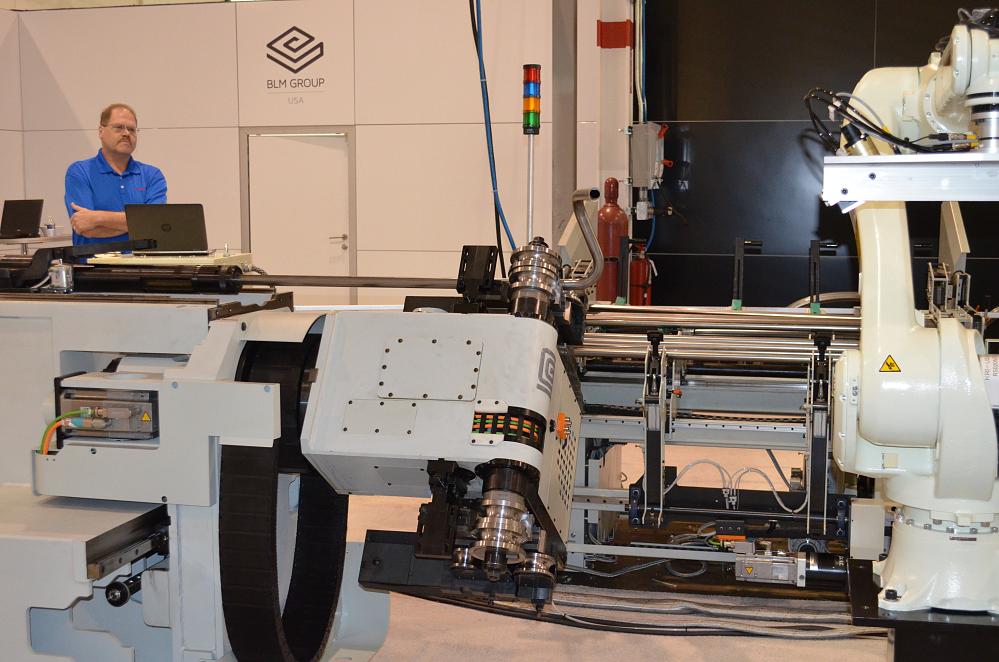

Figure 1. Richard Johnson of BLM Group takes a question from the trade press as he demonstrates the camera feed from the laser cutting chamber on the LT8.10 fiber laser tube cutting machine.

It was only 2001 when the BLM Group USA set up shop in Michigan with a table and some folding chairs. In early June at its Tube Innovation Week, the company announced plans to move to a new, 75,000-sq.-ft. facility near its current home in Wixom, Mich.

This will be the third move for the tube fabrication equipment company in its 15-year existence in the U.S. It currently operates out of a 32,000-sq.-ft. facility where it stocks equipment, holds an inventory of spare parts, and maintains a sales and service organization for North America.

BLM Group President Jeffrey Ahrstrom said that the company has been able to maintain aggressive growth in the metal fabricating industry because it constantly reinvests in research and development.

“You have to invest in the new technology. You have to stay on the cutting edge,” Ahrstrom said.

This was on display for the customers visiting the open house event. For example, they got to see the model LT8.10 fiber laser tube cutting system (see Figure 1). The 3-kW laser is capable of cutting various angles, including a miter cut, on many metals. It can accommodate tube diameters up to 9.5 in.

Ahrstrom said the fiber laser technology represents an overwhelming portion of the company’s equipment sales at the moment. In 2016 the percentage of fiber laser cutting machines being sold compared to the percentage of CO2 machines is about 80/20, Ahrstrom added. He expects fiber laser technology to continue to grow in acceptance as fabricators learn of the equipment’s performance attributes and its minimal maintenance requirements.

The LT8.10’s new laser cutting head was designed in conjunction with Precitec, a laser equipment supplier. (The intellectual properties of the laser cutting head are owned soley by BLM Group and can be found only on the company’s equipment.) The laser cutting head is much more compact and lightweight than previous models, allowing it to work its way in and out of challenging cuts. Company officials believe that it is able to deliver tilt cuts with greater accuracy and quality.

Visitors also got to see the company’s LT Free 5-axis fiber laser cutting machine, which was designed for working on 3-D formed parts, such as bent tubes, hydroformed tubes, welded assemblies, and even stamped parts. As part of this equipment’s design, the workpiece doesn’t move during the cutting operation; it remains stationary as the cutting head moves around the workpiece.

Figure 2. The E-Turn electric tube bender has 15 axes of movement. BLM Group officials consider the equipment a suitable fit for the furniture, pipe, and automotive industries and job shops that serve those industries.

BLM Group demonstrated the equipment in its “high flex” mode, where a robot grabbed the part and held it in position as the laser cutting head moved around it. The 5-axis laser is also available in a “piece value” version with a rotary turntable and automatic load/unload and an entry-level version with dual fixed tables, where a part can be unloaded and loaded while the laser cutting device works on the other table.

Attendees also had the chance to see the company’s LC5 laser cutting machine, which accommodates tube and flat sheet blanks; E-Turn electric tube bender (see Figure 2); and BLMelements tube processing software in action.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Class is in session for college connections

BlueForge Alliance partners with Nuts, Bolts & Thingamajigs to develop Submarine Manufacturing Camps

Portable system becomes hot tech in heat treatment

Orbital tube welding webinar to be held April 23

Cidan Machinery Metal Expo 2024 to be held in Georgia May 1-2

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI